ÖBB (Austrian Federal Railways Holding Stock Company) has more than 250 tunnels to guide trains through the alpine country as quickly as possible. Many tunnels are located below the groundwater level. Accumulating groundwater must be drained in order to maintain traffic.

In summer 2020, Pörner Vienna was contacted by ÖBB-Infra to provide technical support as a plant engineer for this pervasive issue.

Groundwater entering tunnel systems is usually trapped behind the tunnel lining and discharged via drainage pipes. Mountain water naturally contains many different minerals, which lead to rapid sintering of drainage pipes. Therefore, they must be regularly maintained and cleaned to avoid clogging and damage.

Until now, this has been done by using suction/flusher vehicles known from sewer cleaning. For this purpose, the vehicles are loaded onto a maintenance train with flat wagons and moved into the tunnel. Through special central flushing shafts the drains are cleaned with high-pressure flushing nozzles. The glaring disadvantage of this method: the track is blocked by the maintenance train.

Lower maintenance costs and higher availability

Since cleaning means blocking the track, the directional lane or even the tunnel, the cleaning process must be as efficient and fast as possible. This is where the new modular rail drainage flushing system – short MDB – comes into play – a completely new development based on existing and proven systems for similar applications.

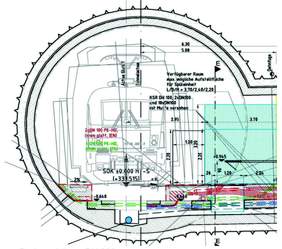

This concept is now being developed into a specialized product for the southern line with the Semmering Base Tunnel, Koralm Tunnel and Granitztal Tunnel. All system components required for flushing are installed in a common, self-propelled housing. Thus, the MDB can be placed above the central flushing shaft in the cross passages of the tunnels, the maintenance train leaves the tunnel and the rail remains free. The MDB is remotely controlled from the tunnel’s respective plant service center (ASC). Thus, there is no personnel in the tunnel and the rail can be used without restrictions.

Pörner – the infra engineering partner

Since ÖBB-Infra – the company in the ÖBB Group responsible for maintenance – was looking for a plant engineering company, Pörner comes into play. The two companies already successfully cooperated during dewatering of the pilot tunnel of the Semmering Base Tunnel in the late 1990s. Now with the third contract award, Pörner is supporting ÖBB-Infra in two concept phases including technical development and providing basic engineering. Basic engineering was completed on schedule in December 2021.

The particular challenge for Pörner is the development of the robotics to be installed in the machine; the enormous reach of 500 m and the associated hydraulic requirements, so that this prototype will ultimately lead to a small-series production.